SAY the phrase “process improvement” and watch the eyes of a CEO roll back in their head. They recoil from conversations about the touted virtues of process improvement methods like Six Sigma, Lean Manufacturing or Business Process Re-engineering as they are inclined, and rightfully so, to talk about the results they want, not the methods to achieve them. Their demand – give me a process improvement method that is simple to apply, contributes to growth/profitability and ensures sustained results over time.

First Step – Determine which processes drive competitive value to warrant an improvement investment. The CEO and the executive team must have a common understanding and agreement of the company strategy and cost drivers impeding performance. This will focus the executives on the correct process improvement projects that drive competitive advantage and value.

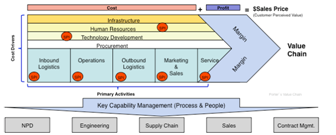

Process concerns usually start with growth and profitability discussions. This translates to – What are the cost drivers negatively impacting our performance? Or, what opportunities exist to improve performance value and gain a competitive advantage? In either case, answers reside within the cost/performance elements of the company’s supply chain (ie, Porter’s value chain concept model).

Supply chains must promote the strategic profile of the organization relative to the products offered and markets served. Without a clear supply chain picture, there is a risk that process improvements projects will not advance the right processes activities critical to product/market growth and profitability.

Second Step – Apply a simple methodology that creates value and reduces costs by eliminating inefficiencies.Regardless of the improvement methodologies to be applied (Six Sigma, Lean, Business Process Re-engineering), they all strive to design visible, optimal, and valued performance. However, complex methodologies are simply not necessary 90% of the time. Applying a question-based approach (ie, Thinking Dimensions’ Design, Execute & Control – DEC methodology) along with the appropriate process design team – of suppliers, performers and customers – is sufficient, less costly and faster to accomplish. Why, the method is simple and the assembled team knows the strengths, weaknesses of the targeted process improvement and they have a vested interest in attaining the desired results.

The process team applying the improvement method must ensure all designed process activities are:

1) Value-Added (necessary action)

2) Redundancy Free (unnecessary tasks)

3) Continuously Flowing (smooth hand offs, no bottlenecks)

4) Performed in Parallel (where possible to reduce cost, cycle-time)

Third Step: Implement the newly designed process so people performance is linked to the desired results.People create value through the process activities they perform. Many process improvement methodologies/projects neglect to change the behaviour of those performing the work in relation to the new process design. People are creatures of habit, and change is not necessarily accepted. If performers do not adhere to the new process activities, the desired results are not attained and management correctly perceives the improvement investment as a waste. Aligning people/process performance is essential, but not always done.

Three factors will ensure people adhere to the new process activities:

1) Clarify the Roles and Responsibilities of all performers

2) Link people’s performance reviews to results of the new process design

3) Dedicate management focus to the implementation

Fourth Step: Manage and sustain results through data, ask:

What would tell you the process improvement investment delivered the desired results? Feedback from your Supply Chain’s key performance indicators (KPI) — cost, quality or schedule performance. Ensure a direct linkage from your KPIs down to the process metrics that contribute to that KPI calculation.

What would tell you if the results are being sustained? Consistent data trends overtime. Company data is often poorly organized to intuitively and quickly assess performance over time, or there is data overload that is confusing. Data should be displayed in “trends over time” so the decision maker can see results and initiate the appropriate inquiry.

How do you manage future performance results? Use the trend data from Supply Chain KPIs to make decisions to manage business processes. Data linked to the processes creating value expedites the targeted resolution. By using data, you are managing process performance and sustaining results.

Recap – The Path to Process Performance management:

1) Determine which process drive competitive value

2) Apply a simple improvement methodology that creates value

3) Link people performance to the desired results of the process

4) Manage results through data