As CEO’s seek to understand the performance of their business, they construct elaborate Key Performance Indicators (KPIs), Strategic Performance Indicators (SPIs), or some other “acronym of measures” all designed to tell them how the company has performed.While such measures are important, they reflect the “past tense” of business performance and, in essence, they are lagging indicators. CEOs and consultants advising them are doing a disservice to the organization if they do not demand of the Value-Chain process managers to establish “leading” measures that warn of pending performance.

Why is this important?

1) Ability to manage verses react too business performance issues

2) Speed of corrective action to resolve value-chain performance issues that impact profitability (P&L) and growth.

Manage verse React – Value-Chain KPIs fall into four basic categories of measures:

1. Quality of Product or Service

2. Timeliness of Delivery

3. Cycle-Time of Production

4. Efficiency (or cost) to Produce, Market and Deliver products.

The KPI may be called different names, but the business interest for their positive performance remains the same – delivering a quality product or service on time at the target cost.It is the value-chain processes and their respective KPIs that provide the appropriate Quality, Timeliness, Cycle-Time and Efficiency performance data (the balanced scorecard) for executive decision-making.But, these measures only tell the story of results passed.

The sub-element measures of the value-chain processes that cascade up to define a KPI are often insufficient or poorly constructed to help executives or value-chain process owners understand what is causing specific performance of a key KPI. When a KPI reflects negative performance and the CEO asks, “what is the issue causing this performance”, the responsible party usually notes they will have to investigate further to get an answer.Effectively placed measures within sub-value chain processes would negate this problem and afford the responsible executive an answer readily at hand.

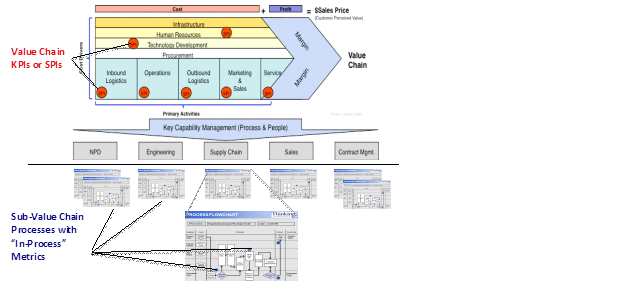

How?Design and install “in-process” measures at key risk areas of sub-value chain processes.Process owners or managers should start by asking, “what KPI or SPI is my sub-value chain process primarily contributing? For example, if the Out Bound Logistics value-chain element (see diagram above starting from the Michael Porter Value Chain framework) is a key source for the Timeliness of Delivery KPI, then assess where in the flow of the various Out Bound Logistics sub-processes is on-time delivery most at risk?Now design and place the appropriate “in-process” measures that provide data, and act as a trigger, of potential on-time delivery issues.

Measures placed at key risk areas of the process provide managers meaningful, and early, insight to the respective KPI or SPI.They are managing the performance of the process, and not simply reacting to lagging indicators.Sub-value chain early-warning measures should be reviewed frequently to see trends that demand corrective action.This data provides more detail of where in the overall value-chain issues have emerged.

Speed of Corrective Actions – In-process measures are predictors of end-of-process performance.If an in-process metric is showing a negative trend (i.e., key paperwork is delayed in the logistic process, or the quality of the paperwork is lacking), it is likely to impact the planned on-time performance.When process managers have the ability to see, early, where in the process issues arise, they also know where to pinpoint their corrective action focus faster.In reality, if they manage processes via in-process metrics, they can anticipate problems (and CEO questions) and be prepared with a more proactive answer to resolution. Mean-time-to-resolution is critical to profitability.

The Key Learning Point – Simply relying on end-of process business measures puts decision-makers in a reactionary position as they lack the data to expeditiously resolve performance issues.

CEOs and business executives should look at their company’s key sub-value chain process flows (assuming the flows exist) and see what and where measures exist.Likely the measures are on the outputs of the process and not areas within the process where true risk of performance resides.

Recap – Stop Reacting to Results and Learn to Manage Performance:

1) Analyze Sub-Value Chain process flows (or define them if they do not exist).

2) Ask what sub-processes have the most impact on the performance of KPIs/SPIs?

3) Ask where in the sub-process is the desired KPI/SPI performance most at risk?

4) Install appropriate “in-process” metrics at high-risk areas of key sub-processes.

5) Start managing performance

This blog was authored by Keith Pelkey.

Other writings related to Process Performance authored by Keith Pelkey- Partner, Thinking Dimensions Global

- Are Your Business Processes Creating Value? www.blog.thinkingdimensionsglobal.com

- Simplify the Path to Process Performance Management““

- Managing Competitiveness Through Product Development““

- Seize Control of Your Business Performancewww.thinkingdimensionsglobal.com