It is reassuring in operations when the probability of a negative event occurring is limited. In reality though many small problems recur and cause significant problems, because they are not properly addressed, often creating significant production and financial loss. Such lack of operational efficiency is often hidden in the finances of an operation, to eventually show up unexpectedly.

Prevent Recurrence of Incidents: Operational Efficiency and Recurring Problems

By Adriaan du Plessis on Nov 8, 2017 3:08:03 AM

Evaluate Plans for Risk: Scope Creep and Budget Overrun

By Adriaan du Plessis on Oct 30, 2017 10:20:29 PM

Evaluate Plans for Risk

By Marcin Kosewski on Oct 23, 2017 9:52:12 PM

Being persistent and precise, pays off when problem solving.

A client was assisted with an internal problem solving session. A lot of time was spent analyzing a long standing problem. This problem was a "worst ever."

Transactional & People Problems

By Adriaan du Plessis on Oct 7, 2017 12:08:37 AM

Operational Problem Solving Strategies in Transactional Environments

Reliability - Root Cause Analysis

By Adriaan du Plessis on Jun 16, 2017 10:18:13 PM

Thought Leadership - Problem Solving and Decision Making

By Adriaan du Plessis on May 19, 2017 1:08:00 PM

Boosting Efficiency By Supporting Critical Thinking Growth In Your Organization

Don't Be a Victim of Vague Managerial Problems

By Adriaan du Plessis on Jun 23, 2015 4:46:59 PM

Recently during facilitation, it struck me how unable the group was to focus and commonly agree what the problem was they are facing. It was common knowledge that they did not have much time to interact with one another and that they had few facts available to them individually. The vague ‘managerial problem’ would, without good interaction never receive the appropriate focus it deserves, because of unintended "silositus."

Future Risks as a Problem – Be Proactive

By Adriaan du Plessis on Jun 17, 2015 4:54:00 PM

I often hear, "we knew that this would happen at some point, but …" Worst of all, in such an scenario people also state that they knew why such future event would occur! We all hope and believe that nothing will go wrong in respect of the things we plan and do, and this belief in our own judgment drives us to believe in our own actions, and rightly so.

Problem Solving Sessions - Worthless Without the Right People

By Adriaan du Plessis on Jun 9, 2015 8:17:17 PM

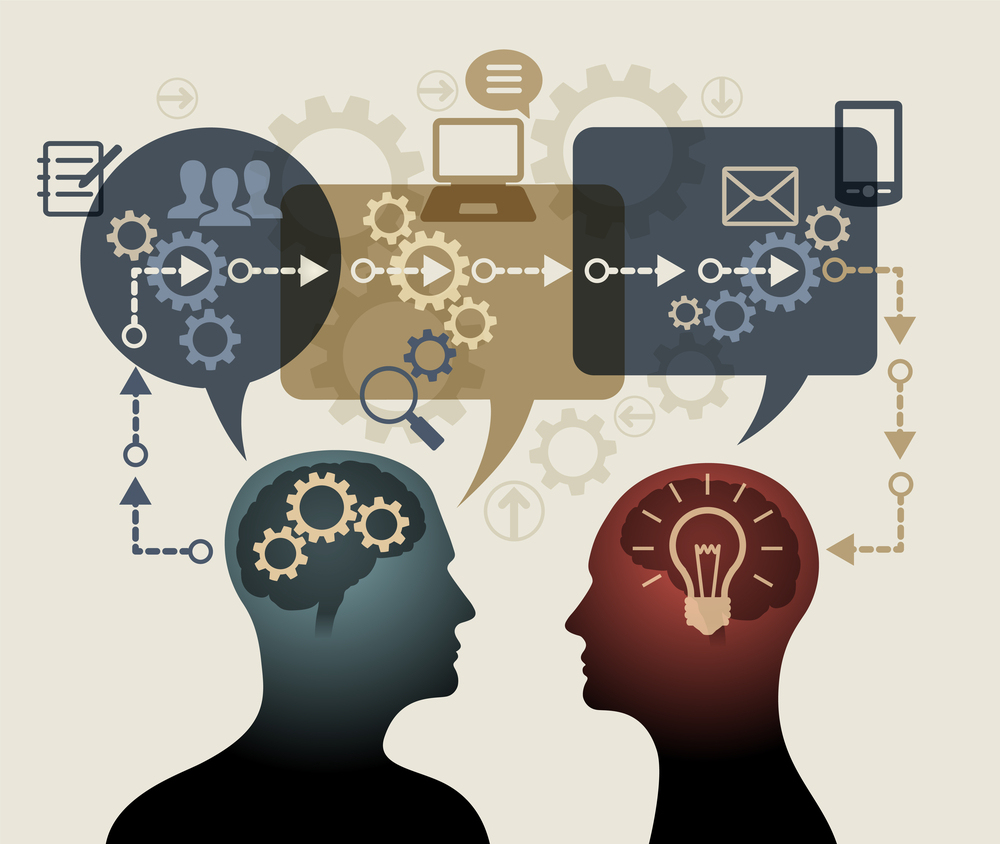

Recently, whilst facilitating both a problem solving session and on a second occasion a decision making session, it struck me again how worthless these processes are in the absence of the right people. The two experiences were such a contrast, that I needed to write about them.

Quality of Information - A Critical Input to Industrial Problem Solving

By Adriaan du Plessis on Jun 2, 2015 4:25:26 PM

Fruitless debate occurs often when intending to solve industrial problems. Such time waste is a function of (1) poor problem solving process and (2) worthless data and information. This short review will focus on the quality of problem solving information.

Information - the Key to Performance Improvement

By Nick Bickell on May 19, 2015 3:43:41 PM

One of the most common, and useful measures of operational profitability for many organisations is COST per UNIT.

Unfortunately this concept is discussed at higher management levels, but rarely at lower levels.

Lower down we tend to talk about volumes and operating costs in isolation with little reference to each other. This results in the much debated problem of chasing volumes while ignoring costs. The converse also occurs frequently with equally damaging results.

Is the Customer Your #1 Stakeholder?

By John Hudson on May 14, 2015 12:05:45 AM

(Blog 5 of 5)

-Henry Ford

There is a need to create a positive touch point on every interaction with a customer. This is not as simple as it sounds for in the ever expanding technology of today the majority of interactions with customers tend to be on-line or remote connections. We are getting fewer and fewer opportunities to have a positive interaction, which means the opportunities that we have, must be positive and fulfilling. How can we possibly ensure this is going to happen?

Creation of Hybrid Solutions through Consensus in Team Problem Solving

By John Hudson on May 6, 2015 5:28:44 PM

(Blog 4 of 5)

Any Fool can know. The point is to understand.

- Albert Einstein

The above Einstein quote is one of my favourites, partly because it is more relevant today than it has been at any other time in history. “Any Fool can know” - and if they don’t already know a quick search in Google using a selection of key words will soon give them the answer - For Example the information relating to the sinking of the Titanic over 100 years ago

- Question - Which passenger ship sunk by iceberg? - The Titanic

A more difficult question to pose and if you are looking for the more important pieces of information!

- Question - “Why did the Titanic sink?”

The Thinking Behind the Process

By John Hudson on Apr 28, 2015 4:13:00 PM

Blog 3 of 5

The world as we have created it is a process of our thinking. It cannot be changed without changing our thinking.

-Albert Einstein

In Part 2, we discovered how a group of participants coped with being exposed to the Polestar Business Simulation. It is important to reiterate that the participants were totally unprepared for the exposure and were expected to fail abysmally, which they did!

Creating Order from Chaos

By John Hudson on Apr 22, 2015 9:19:00 PM

Through Simulation to Exasperation (Blog 2 of 5)

You will have noticed this is Part 2 and as such is a continuation form “Viewing the Problem from the Customer's Shoes.” We have taken 16 unsuspecting participants and are about to launch them into the Polestar business simulation to help them to better understand the business they are in (Their Day Jobs). This is the first step in creating order from chaos.

Viewing the Problem from the Customer's Shoes

By John Hudson on Apr 14, 2015 5:19:00 PM

Blog 1 of 5

When we interact with our clients in the problem management workshop, it is often difficult to get them to understand the situation from a different perspective. This is often the case when it comes to putting themselves “in the customer’s shoes,” to appreciate the negative or “knock-on” effects the customer is experiencing. I suppose we could sit them down in front of an irate customer and let the customer verbally abuse the unsuspecting staff member for a few minutes - I would view this method as being counter-productive!

Possible Risks in Root Cause Analysis

By Pieter van Staden on Apr 7, 2015 8:50:27 PM

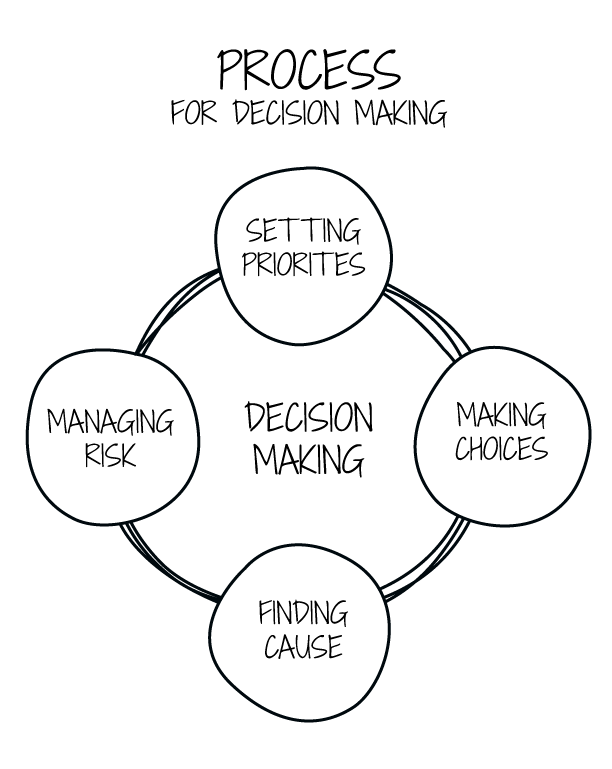

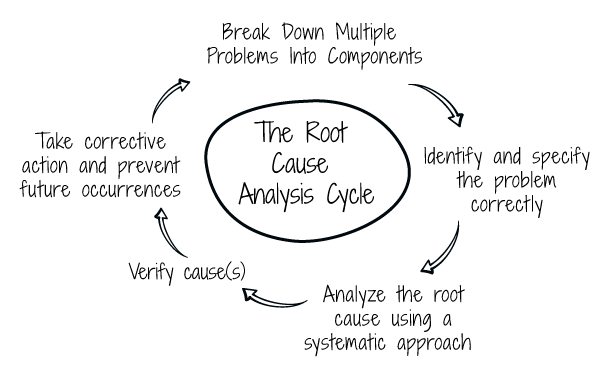

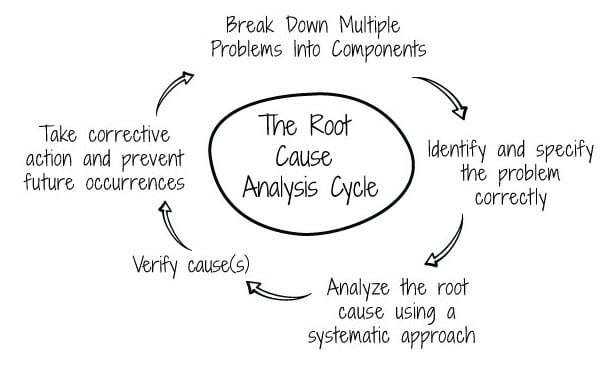

Finding and resolving the root cause of any problem is a fundamental focus of problem solving and decision making. Quite a number of typical methodologies are available to do root cause analysis but regardless of the tool to be used, any process should include at least the following steps or sub processes:

Facilitation Process to Create Focus Where None Exists

By Pieter van Staden on Mar 24, 2015 3:45:31 PM

Solving problems and creating optimum solutions is often not as simple as just following a linear facilitation process and getting to answers. Added complexity and involvement of several stakeholders requires an approach that can align different inputs towards sustainable solutions. However, from experience, we know that the more input from different sources the higher the risk of lengthy discussions and diverse non-focused results with extensive wasted time and cost.

The Formula for Stable and Dynamic Change

By Keith Pelkey on Mar 10, 2015 2:18:12 PM

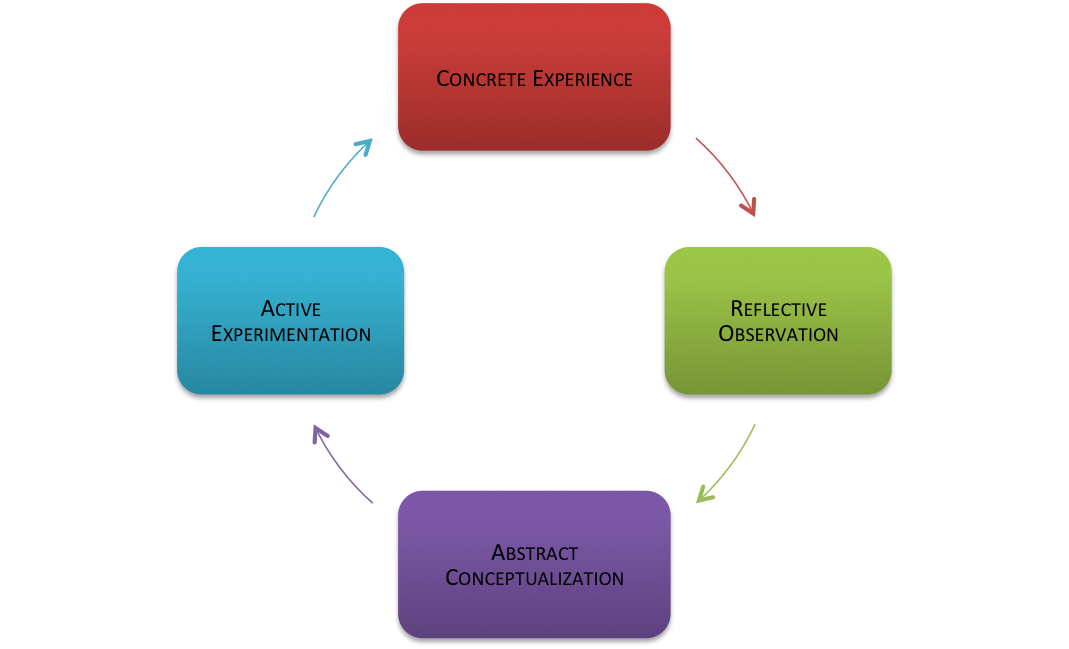

All businesses seek continuous improvement, but it only happens through change. Change is accomplished when management sets clear, unwavering expectations for the organization to repeatedly apply the right “thinking” tools to build the experience required to affect/sustain change that delivers the desired results. Change is about influencing “hearts and minds,” it is systematic, and it is manageable.

Business Imperative to Accelerate Operational Improvement Initiatives

By Keith Pelkey on Mar 3, 2015 11:55:00 PM

Companies need and demand fast results to be competitive! Since the late 1980s, top performing businesses have ventured into various operational improvement methodologies with mixed results. The marketing of methodologies promotes that “the new” approach is better, easier, or more sustaining – hence TQM, Six Sigma, Malcolm Baldrige, Lean Mfg, ISO 9000.

Key Capabilities Create the Value that Drives Competitive Advantage

By Keith Pelkey on Feb 24, 2015 5:09:00 PM

Guidelines for Effective Root Cause Analysis

By Adriaan du Plessis on Feb 10, 2015 8:33:00 PM

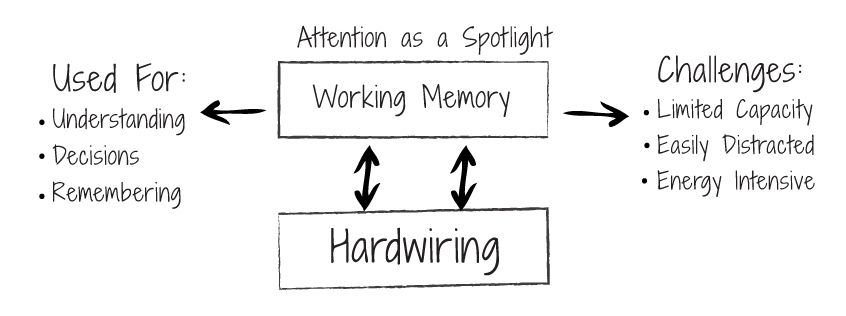

The simple answer is, you put a pen on paper and start drawing. A lot can be learned from this statement when considering whether a root cause analysis effort is effective. Often there is a lot of initial inertia and people arguing as to how the root cause process should be structured. An effective process will be of such a nature that you can start work on the problem immediately, such as gathering and organizing information, without unnecessary time delays.

RCA Facilitation for Complex Problems

By Adriaan du Plessis on Feb 3, 2015 6:07:00 PM

- Subject Matter Experts and Process –

Problem Solvers are often asked to facilitate a root cause analysis session because the problem owner is of the view that the problem is complex. This article will focus on “how to process/facilitate a root cause analysis for a complex technical problem,” and the use of Subject Matter Experts (SMEs).

What I Would Do Differently in 2015...

By Mat-thys Fourie on Dec 23, 2014 3:58:00 PM

As a consultant, I interact with a wide variety of problem solving situations, from Nuclear, Project Office to Information Technology. However diverse the industry the pitfalls are still the same. The following are four interesting but important lessons, when followed would make a world of difference in leading problem solving sessions in 2015.

That is Root Cause... Really?

By Mat-thys Fourie on Dec 9, 2014 3:49:28 PM

I’ve been working with Root Cause Analysis practices for the last 29 years and never found so many different views on Root Cause as in the IT Industry. The term “root cause” is loosely used to describe many kinds of causes and we need to clarify this first.

Why Do Some Improvement Projects Fail?

By Nick Bickell on Dec 2, 2014 5:54:49 PM

In all organisations at any point in time, there are a number of initiatives under way to improve performance. These may be formal or informal, generated in meetings or in the tea room, part of a company wide Continuous Improvement Drive, products of a suggestion scheme or quality circle, knee-jerk reactions to recent incidents etc.

Beyond the 5 Whys... Reunion with Root Cause

By Bill Dunn on Nov 25, 2014 3:41:56 PM

Recently I attended my 40th college reunion. I saw lots of old friends and I enjoyed lots of small talk with people whose names I could recall but not their faces. I had a revealing and rewarding discussion with one of my classmates who had made a big name and a small fortune for himself in the business world. When he asked what I was up to, I kept my response deliberately vague. I replied “Consulting.”

He pressed me. “What type?”

New decision making approach - far different than old approach!

By Adriaan du Plessis on Nov 18, 2014 7:45:47 PM

During the 1980’s, we were all taught that decision making requires us to think in terms of objectives, alternatives and potential risk. In essence, methodologies focused on making a rational choice and selecting a viable alternative to implement. Whilst objectives and potential risk remain a constant feature, we need to critically review the concept of alternatives in current day decision making.

The reason for critical review is two fold. Firstly, potentially an alternative may only provide a part of the future decision outcome, or worse, the decision outcome we are seeking does not have alternatives at present. The latter is often visible when required to decide solutions for the Information Technology problems. As Charles Kepner (KEPNER et al (1981). The New Rational Manager.) already postulated in the eighties, the outcome of a decision is “what ought to be done”. This notion of what ought to be done actually implies more that just choosing between alternatives, it postulates that decision making must be a “solution creation” exercise.

How to Avoid Risks Destroying Your Day!

By Mat-thys Fourie on Nov 4, 2014 4:05:11 PM

You want to do what?!

Human beings have no problem getting themselves out of trouble, but do have a major problem anticipating potential risks. The pitfall of modern business in most situations is that we are dealing with major new initiatives and constant changes, but we are not seeing the “blind spots”.

Find Root Cause First Time Every Time

By Adriaan du Plessis on Oct 21, 2014 4:19:45 PM

We often do ‘root cause analysis’ and conclude that a specific cause is present, for which cause we promptly proceed to solutions, to only find in due course that the same problem recurs. While in such cases we may seem to be following proper process, we are in actual fact not doing so, else the problem would not recur. As people who have a natural tendency to jump to conclusion and to fix urgently since this solves the issue. For tougher problems, to avoid this pitfall, we can exploit the human inclination of quick conclusion and solution, and add a little patience and use more time.

Try the following sequence (if you are familiar with a KEPNERandFOURIE CauseWise at all levels, this adjusted approach will be familiar to you):

- Do a Proper Problem Statement with Object and Fault.

- List 2 or 3 critically unique features of the problem.

- Now accommodate your urge and list possible causes.

- Test the possible causes using the “Thinking On Your Feet” Approach, and eliminate those possible causes that is clearly not the cause. This results in a short-list of possible causes.

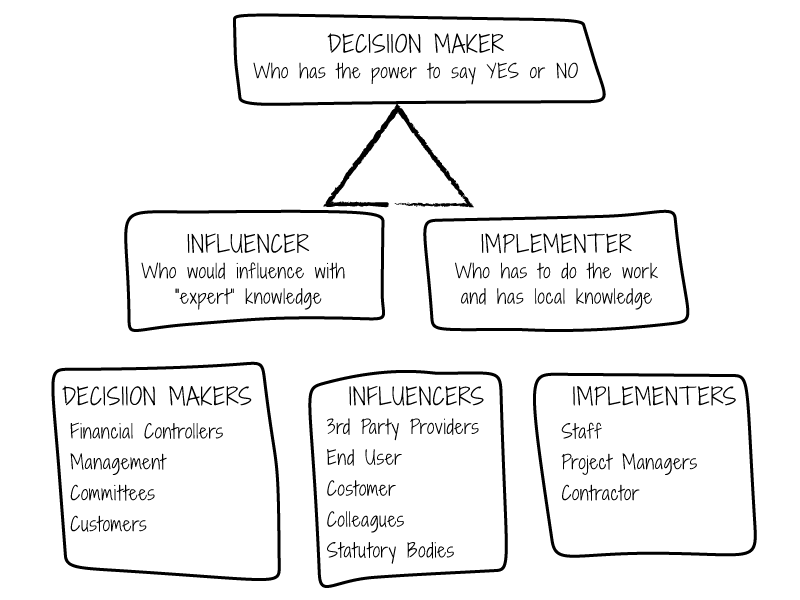

The Benefits of Stakeholder Analysis

By Adriaan du Plessis on Oct 14, 2014 5:22:00 PM

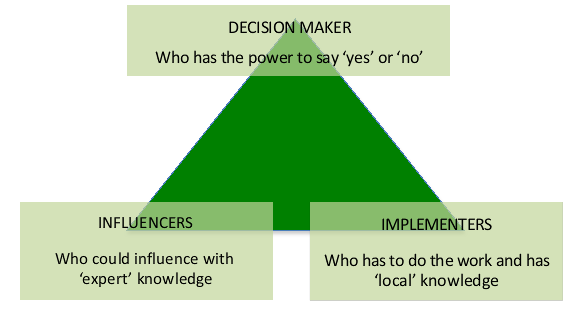

IT Service Management Players mostly need to make decisions in a short period of time, failure to make quick effective decisions will delay solutions being implemented and therefore also customer experience. Involving stakeholders who affect or may be affected by the envisaged decision, sounds onerous, when fast solutions are necessary.

Implementation - This is the Acid Test of Good Leadership

By Mat-thys Fourie on Oct 7, 2014 4:06:07 PM

So many times, teams would work tirelessly to develop the best possible solution for a company to emerge from a disaster or to achieve a highly valuable objective, just to see all their efforts going up in smoke. We never seem to find a problem with the motivation of the team at the beginning of a project, but somehow that same team loses their motivation and will to effectively implement a solution.

STAKEHOLDER ANALYSIS

By Mat-thys Fourie on Sep 30, 2014 6:35:00 PM

THE ANCHOR FOR SUCCESSFUL DECISION MAKING

Today, let’s talk about the first and most important one – stakeholder inputs. We could make a statement that the level of collaborative inputs equals the level of implementation commitment and we will not be far from the truth. In fact the following equation is most applicable in decision making:

Root Cause Analysis = Cost Reduction

By Adriaan du Plessis on Sep 23, 2014 4:07:00 PM

(Even if we often do not believe it!)

You often hear from problem solvers that while they solve sticky organizational issues, their bosses do not actually believe that their work activity contributes to the bottom line. The foregoing may often result because the relevant decision maker does not make a link between work activity and revenue generating ability in a business. However, we have to accept that all activity in a business, at some point will find its way to the income statement, either above or below the line, affecting the profit calculated.

How To Leverage Your Maintenance Department for Significant Cost Savings

By Mat-thys Fourie on Sep 16, 2014 5:06:00 PM

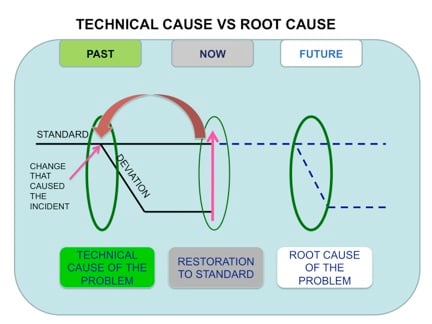

Maintenance departments are normally associated with high costs, long wait times and recurring operational issues. This image could be eradicated within a very short time by understanding the difference between “technical cause” and “root cause.” The emphasis is always on fixing the issue so that we can have production running again.

Let’s look at the diagram below. Any deviation from standard is something that a maintenance technician is trained to diagnose and fix in a very short space of time. The technician’s focus is about finding the technical cause and not so much about finding the root issue.